In the field of modern building decoration and furniture manufacturing, wall panel as an important decorative material, its production process and equipment selection directly affect product quality and production efficiency. At present, PUR flat laminating machine has become the mainstream equipment for wallboard production, with its excellent performance and efficient production capacity, occupies an important position in the industry. This article will comprehensively analyze the application of PUR flat laminating machine in the production of wallboard, advantages and purchase points.

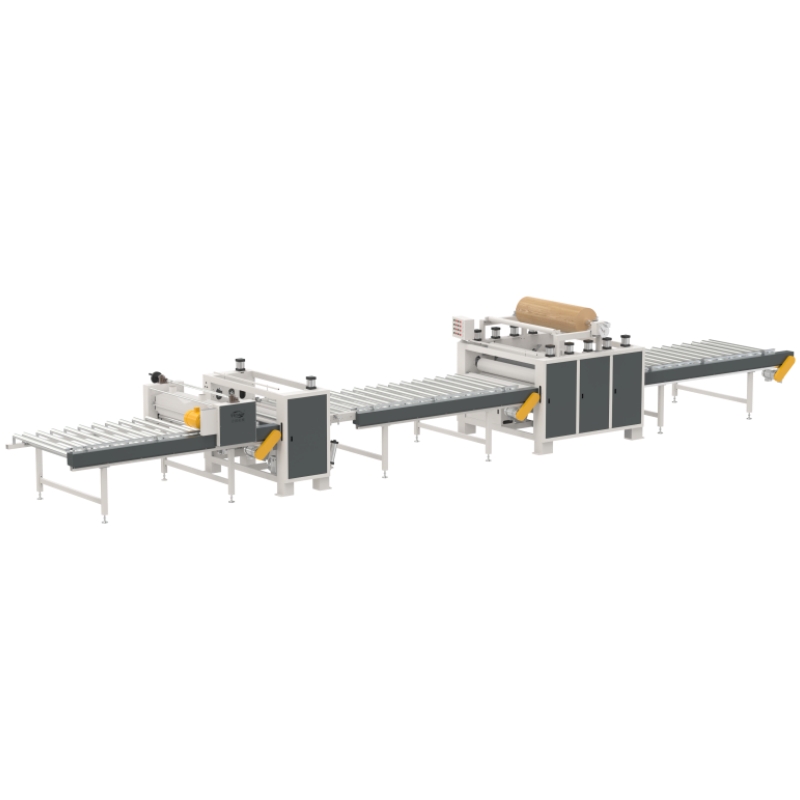

First, the PUR machine: the core equipment for wallboard production

1. Equipment definition and working principle

PUR flat laminating machine is a kind of professional laminating equipment using polyurethane reactive hot melt adhesive (PUR adhesive),

through the precise temperature control and pressure system, all kinds of finishing materials and substrates firmly bonded.

Its working principle mainly includes:

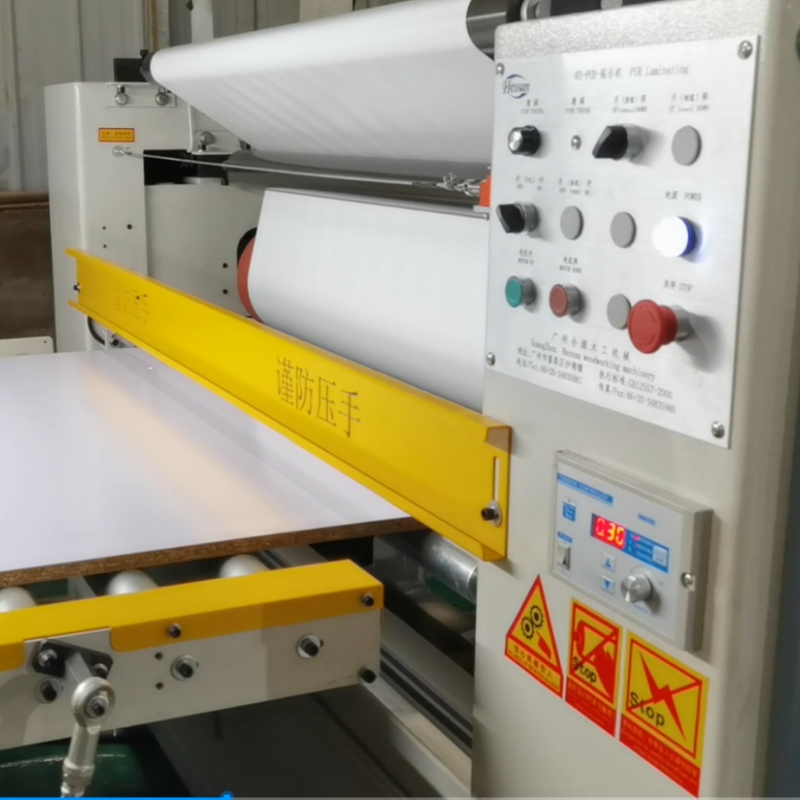

Glue heating system: heating the solid PUR glue to a molten state (about 120-150°C)

Precise coating system: uniform glue application by roller coating or spraying

2. Core advantageous features

PUR flat laminating machine has significant advantages over traditional equipment:

Strong adhesive force: PUR adhesive cured to form an irreversib

le crosslinking structure, peel strength of up to 8-12N/mm.

Efficient production: from sizing to press-fit completion in 30-90 seconds, 5-10 times faster than the manual process.

Environmental protection and safety: solvent-free, very low VOC emissions, in line with the E0 environmental standards.

Wide adaptability: can handle PVC film, decorative paper, PET and other finishing materials.

Second, the application of PUR flat laminating machine in the production of wall panels

1. Applicable wallboard types

PUR flat laminating machine is widely used in the following wallboard production:

PVC laminated wall panels: medical, education and other places special wall panels

PET veneer panels: decorative wall panels for cabinets and closets.

Wood grain paper printed wall panels: decorative wall panels imitating the effect of solid wood

Fireproof board: special fireproof decorative wall panels for public places

2. Typical production process

Substrate pretreatment: sanding and dust removal (surface roughness Ra ≤ 3.2μm)

PUR adhesive coating: coating amount 80-120g/m².

Finishing material lamination: temperature 100±5℃, line pressure 30-50N/cm

Split board trimming: manual cutting of membrane material

PUR flat laminating machine purchase guide

1. Key purchase parameters

| Parameter | Standard Value | Special Requirement |

| Working width | 600mm-1300mm | Can be customized super wide width |

| Working speed | 5-15m/min | High-speed model up to 20m/min |

| Temperature control | ±1℃ accuracy | Better temperature control |

2.Comparison of mainstream brands

German brands: Burkle, Hymmen (high precision, high price)

Italian brands |: Biesse, SCM (cost-effective)

Nationale Marken: Nanxing, HESSAN (guter Kundendienst)

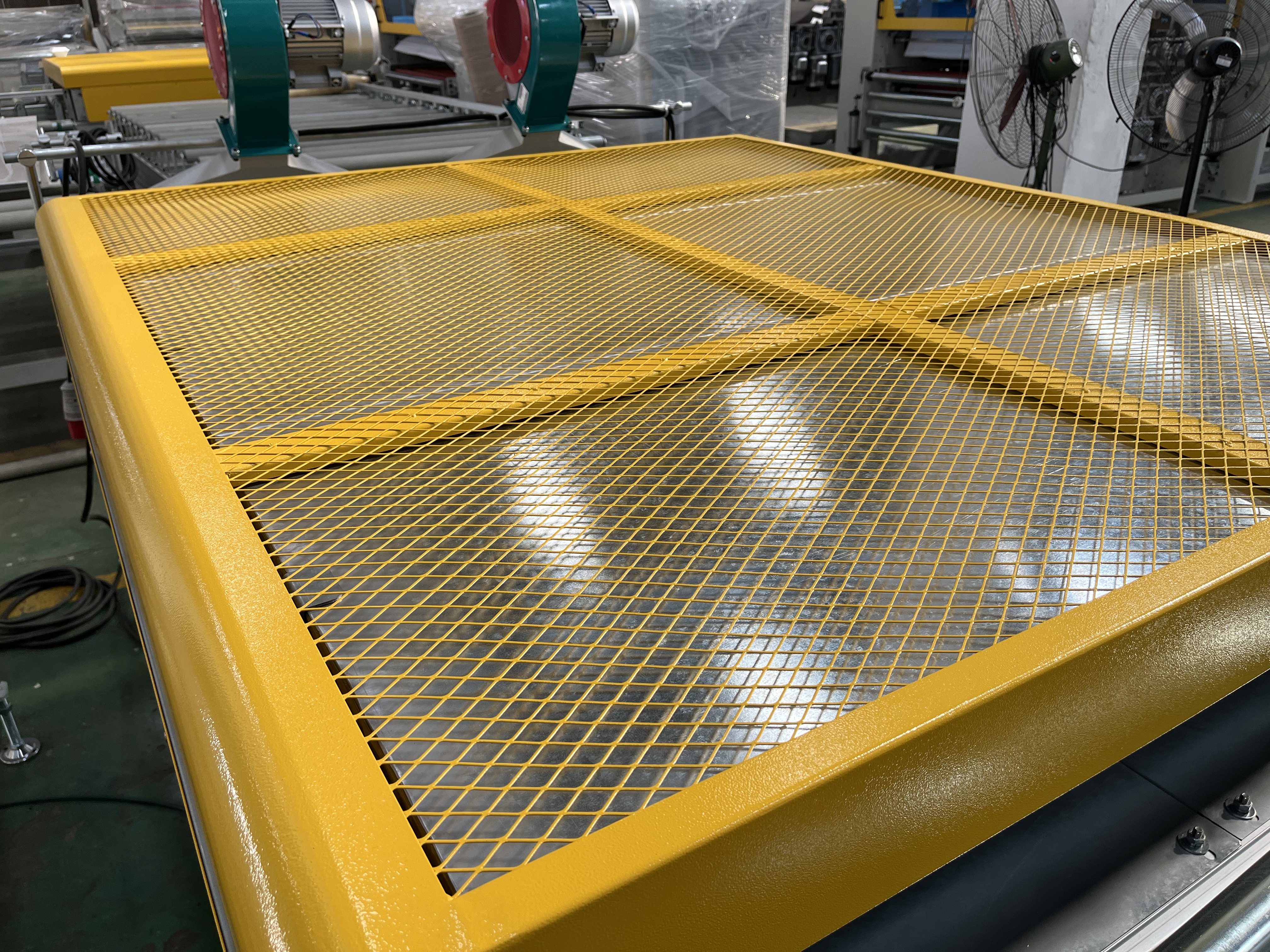

3. Wartungspunkte der Ausrüstung

Tägliche Reinigung der Gummiwalzen und Kupferleitbleche

Überprüfen Sie wöchentlich die Genauigkeit des Temperatursensors

Antriebskomponenten monatlich schmieren

Filter vierteljährlich wechseln

Abschluss

PUR-Flachlaminatoren haben sich dank ihrer hervorragenden Leistung und innovativen Technologie zu einem unverzichtbaren Schlüsselgerät für die Herstellung von Wandplatten entwickelt. Da die Branche der dekorativen Baustoffe die Produktqualität und die Umweltschutzanforderungen kontinuierlich verbessert, werden PUR-Flachlaminiermaschinen auch weiterhin die Entwicklung der Wandplattenherstellungstechnologie bestimmen. Beim Kauf von Geräten sollten Unternehmen Produktionsbedarf, Budget und zukünftige Entwicklung berücksichtigen und die am besten geeignete PUR-Flachlaminierlösung wählen.